Industries

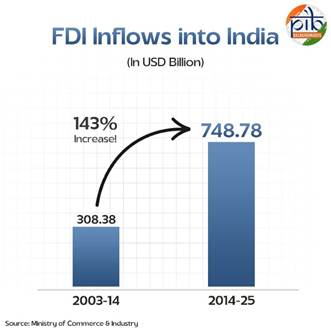

Manufacturing an Atmanirbhar Bharat

प्रविष्टि तिथि:

15 AUG 2025 15:16 PM

A Decade of Make in India and Self-Reliance

Introduction

As the nation marks its 79th Independence Day, India’s manufacturing sector stands as a symbol of self-reliance and progress. Over the past decade, bold reforms and visionary policies under the Make in India initiative have transformed the country into a global manufacturing hub. From defence to electronics, pharmaceuticals to advanced medical devices, Indian factories are producing world-class goods for both domestic needs and international markets. To accelerate this momentum, the Government has launched the National Manufacturing Mission (NMM) in Union Budget 2025–26 with an outlay of ₹100 crore, aimed at boosting innovation, competitiveness, and capacity across key sectors.

This growth reflects the nation’s resolve to reduce import dependence, create jobs, and strengthen its position in global value chains. The journey towards an Atmanirbhar Bharat is well underway, powered by innovation, investment, and the spirit of enterprise.

India’s Manufacturing Footprint

Manufacturing has remained a strong pillar of India’s economic growth. Over the past decade, the sector has expanded steadily, contributing more to the nation’s output and providing steady employment. The value created by manufacturing has seen a significant rise, reflecting higher productivity and greater investment in capacity.

|

Indicator

|

2013–14

|

2023–24

|

|

Manufacturing share in total GVA (%)

|

17.2

|

17.5

|

|

Manufacturing GVA at constant prices (₹ lakh crore)

|

15.60

|

28.25

|

Production-Linked Incentive (PLI) Scheme

The Production-Linked Incentive Scheme, with an outlay of ₹1.97 lakh crore (over USD 26 billion), covers 14 strategic sectors including electronics, IT hardware, pharmaceuticals, bulk drugs, medical devices, telecom products, food processing, white goods, automobiles, specialty steel, textiles, drones, and more. It is designed to boost domestic manufacturing, drive technology adoption, and strengthen India’s position in global value chains.

Key Facts:

- Investments worth ₹1.76 lakh crore have been made till March 2025.

- Generated production and sales of over ₹16.5 lakh crore.

- Created more than 12 lakh jobs, both direct and indirect.

- Incentives totaling ₹21,534 crore have been disbursed across 12 sectors under implementation.

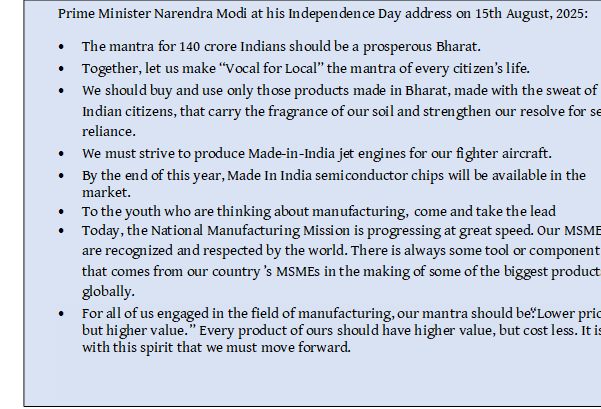

Defence Manufacturing – From Importer to Exporter

India’s defence industry has undergone a remarkable transformation in the past decade. Focused policies, targeted investments, and a strong push for self-reliance have turned the country into a significant producer and exporter of defence equipment. The shift from dependency on imports to building critical technologies within the nation reflects a decisive move towards Atmanirbharta.

Key Facts:

- The value of indigenous defence production reached a record Rs 1,50,590 crore in FY 2024–25, marking an 18% growth over the previous fiscal’s Rs 1.27 lakh crore and a 224% increase from Rs 46,429 crore in 2014–15.

- Defence exports increased from ₹686 crore in 2013–14 to ₹23,622 crore in 2024–25, a 34-fold rise.

- Five Positive Indigenisation Lists have been issued, covering over 5,500 items, of which 3,000 had been indigenised by February 2025.

- Indigenised systems include LCA Tejas, Arjun MBT, artillery guns, assault rifles, corvettes, sonar systems, transport aircraft, light combat helicopters, radars, armoured platforms, rockets, and bombs.

- Export portfolio spans bulletproof jackets, Dornier Do-228 aircraft, Chetak helicopters, fast interceptor boats, and lightweight torpedoes.

- India now exports defence equipment to over 100 countries, with the United States, France, and Armenia among the leading buyers in 2023–24.

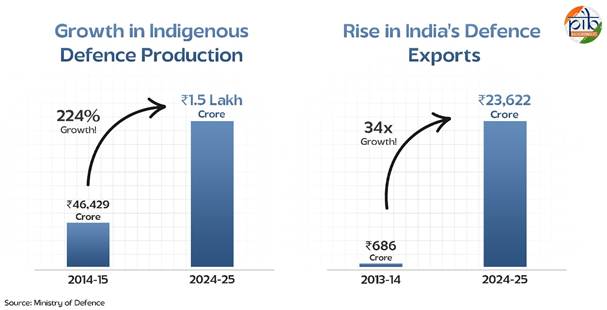

Electronics and Mobile Manufacturing

India has rapidly evolved into a major centre for electronics production. Guided by the vision of Make in India and Atmanirbhar Bharat, the country has achieved exceptional growth in both output and exports. Mobile manufacturing, in particular, has seen a dramatic transformation, making India one of the largest producers in the world.

|

Indicator

|

2014–15

|

2024–25

|

Growth

|

|

Production of electronics goods

|

Rs 1.9 lakh crore

|

Rs 11.3 lakh crore

|

~6 times

|

|

Exports of electronics goods

|

Rs 38,000 crore

|

Rs 3.27 lakh crore

|

8 times

|

|

Mobile manufacturing units

|

2

|

300

|

150 times

|

|

Mobile phone production

|

Rs 18,000 crore

|

Rs 5.45 lakh crore

|

28 times

|

|

Mobile phone exports

|

Rs 1,500 crore

|

Rs 2 lakh crore

|

127 times

|

Pharma and Medical Manufacturing

India ranks third in volume and fourteenth in value in the global pharmaceutical industry. It plays a crucial role in ensuring affordable healthcare worldwide by supplying 20% of the world’s generic medicines and a large share of vaccines. Steady growth in production, exports, and domestic innovation has reinforced its position as a trusted global supplier.

Key Facts:

- The sector’s turnover reached ₹4,17,345 crore in 2023–24, with annual growth of over 10% in the past five years.

- In the first three years of the PLI scheme, cumulative sales stood at ₹2.66 lakh crore, including exports worth ₹1.70 lakh crore.

- India moved from being a net importer of bulk drugs in FY 2021–22 (deficit of ₹1,930 crore) to a net exporter worth ₹2,280 crore.

- Under the PLI scheme for medical devices, 21 projects have started producing 54 unique devices including MRI machines, CT scanners, heart valves, stents, and dialysis machines.

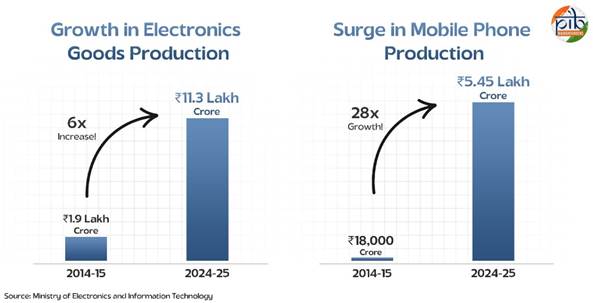

Foreign Direct Investment (FDI) in Manufacturing

India has emerged as a preferred destination for global investors. Over the past decade, steady reforms, simpler regulations and a stable policy environment have encouraged large-scale investments in manufacturing. The focus on ease of doing business and sector-specific incentives has further strengthened India’s position as a competitive manufacturing hub.

Key Facts:

- Between April 2014 and March 2025, the manufacturing sector received FDI equity inflows worth USD 184.15 billion.

- Total FDI inflows into India over the last eleven years (2014–25) stood at USD 748.78 billion, up 143% compared to USD 308.38 billion received during 2003–14.

- 2014-25 accounts for nearly 70% of all FDI, i.e. USD 1,072.36 billion received in the past 25 years.

- Annual inflows rose from USD 36.05 billion in FY 2013–14 to USD 81.04 billion (provisional) in FY 2024–25, recording a 14% increase over USD 71.28 billion in FY 2023–24.

- The Government aims to raise annual FDI inflows to USD 100 billion, building on the current five-year average of over USD 70 billion.

Click here to see PDF

SK/M

(तथ्य सामग्री आईडी: 149250)

आगंतुक पटल : 3973

Provide suggestions / comments

इस विश्लेषक को इन भाषाओं में पढ़ें :

हिन्दी