Ministry of Science & Technology

New technology enables machining of superalloys used in jet engines, nuclear reactors & space vehicles

Posted On:

06 AUG 2025 4:58PM by PIB Delhi

A new technology promises to transform how we cut through some of the hardest materials known to engineering like Inconel 625 (IN625), which are used in areas ranging from aerospace and chemical to nuclear as well as in power production systems, such as boilers, heat exchanger tubes, and steam turbines.

The hybrid technique called Laser-Assisted Turning (LAT), that combines localized laser heating with mechanical cutting of such superalloys using tools coated with materials like tungsten carbide and CrAlSiN nanocomposite as well as the wear mechanisms of tungsten carbide cutting tools during the machining of IN625 superalloy, paves way for next-generation turbine blades, surgical tools, and high-performance automotive parts that are lighter, stronger, and more efficient.

Machining superalloys, the ultra-tough metals used in jet engines, nuclear reactors, and space vehicles, has always posed a challenge. Their exceptional strength and heat resistance — qualities that make them indispensable — also make them incredibly difficult to shape. Traditional cutting tools struggle, suffering rapid wear and producing inconsistent results. But now, ARCI researchers have cracked the code.

Under the Clean Coal Research Initiative of the Department of Science and Technology (DST), researchers at the International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI) have successfully demonstrated the effectiveness of Laser-Assisted Turning (LAT) for machining high-performance materials such as Inconel 625 (IN625), a nickel-based superalloy.

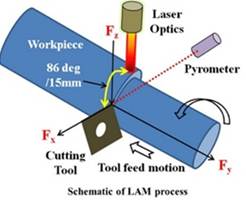

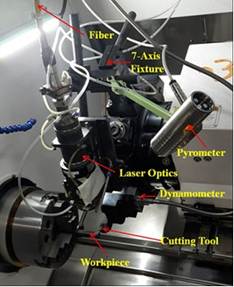

Fig 1: (a) schematic of LAM, and (b) LAM system at ARCI

This breakthrough offers a scalable, high-precision solution for industries that require the machining of difficult-to-machine materials, particularly in aerospace, power generation, and marine sectors.

IN625 is renowned for its exceptional mechanical strength, corrosion resistance, and ability to endure extreme temperatures. While ideal for demanding environments, its inherent toughness poses serious machining challenges, such as excessive tool wear, high cutting forces, and poor surface finish, when using traditional turning techniques.

To overcome these limitations, researchers of ARCI, an autonomous institution of the Department of Science and Technology (DST) developed Laser-Assisted Turning, a hybrid technique that combines localized laser heating with mechanical cutting. A high-power diode laser (up to 2500 W) precisely heats the workpiece just ahead of the cutting tool, inducing thermal softening in the material. This significantly reduces cutting resistance, improves chip formation, and enhances tool life and machining quality.

The study evaluated the turning of IN625 using both uncoated tungsten carbide tools and CrAlSiN nanocomposite-coated tools, known for their superior hardness, thermal stability, and oxidation resistance. When paired with LAT, these coated tools delivered outstanding performance such as, 69% reduction in cutting force, 46% lower tool wear, and 56% improvement in surface finish compared to conventional methods. The team has also investigated the wear mechanisms of tungsten carbide cutting tools during the machining of IN625 superalloy at elevated temperatures.

Fig 2: (a) Tool wear (VBBmax) and (b) Surface roughness (Ra) in conventional and laser-assisted machining of IN625 alloy with uncoated and CrAlSiN nanocomposite-coated WC tools

A key innovation was the integration of a Computer Numerical Control (CNC) turn-mill center with a fiber-coupled diode laser, custom-designed adapters, and real-time monitoring tools.

The novelty of the approach lies in the synergistic use of LAT with advanced tool coatings, a combination not widely explored earlier. These results underscore the effectiveness of thermal softening when paired with surface-engineered tools. The CrAlSiN-coated tools, in particular, demonstrated excellent resistance to wear mechanisms like abrasion and oxidation while maintaining cutting-edge sharpness and dimensional accuracy under high temperatures. Their study wear mechanism of tungsten carbide cutting tools during the machining of IN625 superalloy, revealed that it transitioned from fatigue and abrasion at room temperature to oxidation and adhesion-dominated behaviour at higher temperatures. These insights could help in understanding tool failure modes and estimating the thermal stability and service life of the cutting tool.

This technological advancement published in the journal of Process Mechanical Engineering and Materials Letters offer a significant leap in the machinability of superalloys, opening new avenues for high-strength, high-precision components. It also aligns with India’s strategic goals of boosting domestic manufacturing, improving energy efficiency, and adopting cleaner industrial technologies.

*****

NKR/PSM/AV

(Release ID: 2153110)

Visitor Counter : 230