PIB Headquarters

Driving India’s Electronics Future

First 7 projects under ECMS worth ₹5,532 crore investment approved

प्रविष्टि तिथि:

27 OCT 2025 6:18PM by PIB Delhi

Key Takeaways

- 7 projects approved under ECMS with a total investment of ₹5,532 crore.

- Projects to generate ₹44,406 crore in output and create 5,195 jobs.

- ECMS investment commitments reach ₹1.15 lakh crore, twice the target.

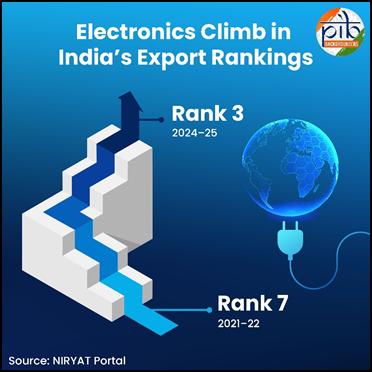

- Electronics has become India’s third largest export category in FY 2024-25.

Introduction

A new chapter in India’s electronics manufacturing story began as projects worth ₹5,532 crore received approval under the Electronics Component Manufacturing Scheme. These first seven projects promise to add fresh energy to the country’s growing component ecosystem, with an expected production value of ₹44,406 crore and over 5,000 new jobs.

The approved projects were announced by Union Minister Ashwini Vaishnaw, signalling a strong push to deepen India’s electronics value chain. The initiative reflects the government’s focus on building a robust domestic base for high-value components to support large-scale manufacturing.

In recent years, India’s electronics sector has achieved extraordinary growth, emerging as the third largest and fastest-growing export category in 2024–25. The ECMS seeks to build on this momentum, driving the nation closer to its goal of becoming a global leader in advanced electronics manufacturing.

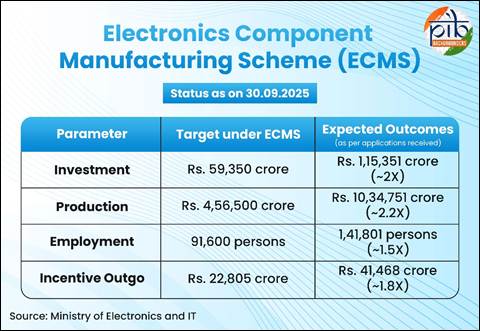

Scheme Overview

The Electronics Component Manufacturing Scheme was notified on 8 April 2025 with a total outlay of ₹22,919 crore, equivalent to about USD 2.7 billion. It has a tenure of six years, with an optional one-year gestation period. The scheme aims to build a strong and self-sustaining ecosystem for electronics component manufacturing in the country. Its focus is on attracting both domestic and global investment across the value chain, promoting higher domestic value addition, and positioning India as a key player in global electronics trade.

The ECMS seeks to integrate India’s electronic industry with global value chains by encouraging production of essential components, sub-assemblies, and raw materials within the country.

As of 30 September 2025, investment commitments under the scheme stand at ₹1,15,351 crore, nearly double the original target of ₹59,350 crore. Production worth ₹10,34,751 crore is expected to be generated over the next six years, which is 2.2 times higher than the initial projection. The incentive outgo is projected at ₹41,468 crore, around 1.8 times the original estimate of ₹22,805 crore. The scheme is also expected to create 1,41,801 direct jobs, surpassing the target of 91,600, along with a large number of indirect employment opportunities.

Products Covered under the First Set of ECMS Approvals

The first set of approvals cover a diverse range of high-value electronic components and materials that are critical to modern technology. These projects will strengthen India’s position in the global value chain by enabling large-scale production of components used across smartphones, automobiles, medical devices, telecommunications, and industrial systems.

Camera Module Sub-Assembly

Camera module sub-assemblies are used in smartphones, drones, medical devices, and robots. They capture high-quality images and videos in electronic devices and serve as the imaging component in smartphones, tablets, laptops, security cameras, automotive systems, and IoT devices.

Multi-Layer PCB

Multi-layer Printed Circuit Boards (PCBs) are used in automotive, consumer electronics, ICT, medical devices, telecommunication, aerospace and defence, and industrial manufacturing. They have multiple copper and dielectric layers that are interconnected with through-hole vias and are widely used in consumer electronics, industrial controls, and automotive systems.

HDI PCB

High-density interconnect PCBs are used in consumer electronics and wearable technology, automotive electronics, medical devices, telecommunication, aerospace and defence. These are advanced versions of PCBs with microvias, blind and buried vias, via-in-pad structures, finer tracks, and tighter spacing. They enable compact, high-performance designs for smartphones, tablets, wearables, aerospace, and medical devices.

Laminate (Copper Clad Laminate)

Copper clad laminates are used in automotive, consumer electronics, medical devices, ICT, telecommunication, aerospace and defence, and industrial manufacturing. They serve as the base component for the manufacture of multi-layer PCBs.

Polypropylene Film

Polypropylene film is used in capacitors for consumer electronics, automotive, ICT, industrial and manufacturing, telecommunications, and computing. It is the key material used in the production of capacitors.

Overview of Approved Applications under ECMS

The initial batch of applications reflects a strong commitment from leading domestic manufacturers to build high-value component capacity within India. Spread across Tamil Nadu, Andhra Pradesh, and Madhya Pradesh, these projects involve an investment of ₹5,532 crore, with expected production of ₹44,406 crore and 5,195 new jobs.

|

Applicant Name

|

Product

|

Project Location

|

Cumulative Investment (₹ crore)

|

Cumulative Production (₹ crore)

|

Incremental Employment (Persons)

|

|

Kaynes Circuits India Private Limited

|

Multi-Layer Printed Circuit Board (PCB)

|

Tamil Nadu

|

104

|

4,300

|

220

|

|

Kaynes Circuits India Private Limited

|

Camera Module Sub-Assembly

|

Tamil Nadu

|

325

|

12,630

|

480

|

|

Kaynes Circuits India Private Limited

|

HDI PCB

|

Tamil Nadu

|

1,684

|

4,510

|

1,480

|

|

Kaynes Circuits India Private Limited

|

Laminate

|

Tamil Nadu

|

1,167

|

6,875

|

300

|

|

SRF Limited

|

Polypropylene Film

|

Madhya Pradesh

|

496

|

1,311

|

225

|

|

Syrma Strategic Electronics Private Limited

|

Multi-Layer Printed Circuit Board (PCB)

|

Andhra Pradesh

|

765

|

6,933

|

955

|

|

Ascent Circuits Pvt Ltd

|

Multi-Layer Printed Circuit Board (PCB)

|

Tamil Nadu

|

991

|

7,847

|

1,535

|

|

Total

|

|

|

5,532

|

44,406

|

5,195

|

Electronics as India’s Leading Export Category

Electronics have emerged as India’s third largest and fastest growing export category in 2024–25, rising from the seventh position in 2021–22. In the first half of FY 2025–26, electronics exports stood at USD 22.2 billion[1], maintaining strong growth momentum and placing the sector on course to become the country’s second largest exported item.

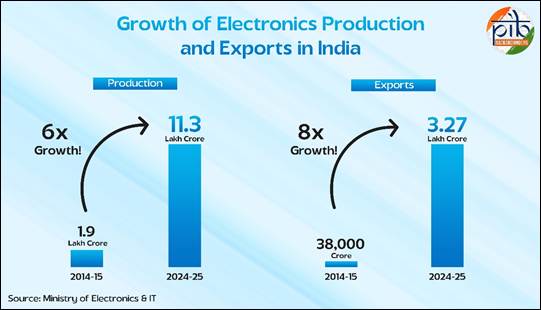

The country’s electronics production has grown from ₹1.9 lakh crore in 2014–15 to ₹11.3 lakh crore in 2024–25, marking a six-fold increase. Exports rose from ₹38,000 crore to ₹3.27 lakh crore in the same period, reflecting an eight-fold jump. Over the past decade, electronics manufacturing has created around 25 lakh jobs across the country.

Mobile manufacturing has played a major role in this transformation. Production in this segment has increased from ₹18,000 crore in 2014–15 to ₹5.45 lakh crore in 2024–25, a 28-fold rise. India is now the world’s second largest mobile phone manufacturer, with more than 300 units operating compared to just two in 2014.

Exports of mobile phones have shown remarkable progress, rising 127 times from ₹1,500 crore in 2014–15 to ₹2 lakh crore in 2024–25. In 2024, Apple alone exported iPhones worth ₹1,10,989 crore, crossing the ₹1 lakh crore mark with 42 per cent year-on-year growth. In the first five months of 2025–26, smartphone exports touched ₹1 lakh crore, a 55 per cent rise over the same period last year.

India has now achieved near self-reliance in mobile production, moving from importing most of its requirements a decade ago to manufacturing almost all devices domestically. This transformation highlights the strength of India’s policy ecosystem and its emergence as a trusted hub for global electronics manufacturing and exports.

Conclusion

India’s electronics manufacturing sector stands at a defining moment. The approval of projects under the Electronics Component Manufacturing Scheme marks not just an industrial milestone but a strategic step towards deepening self-reliance and strengthening the nation’s global position in technology production. With strong investment commitments, record production targets, and steady job creation, the scheme is set to reinforce the foundation of India’s electronics value chain.

From components to complete devices, India is moving up the manufacturing ladder with confidence. The growth in exports, the rise of domestic production, and the rapid expansion of mobile manufacturing together show a clear direction. India is not only producing for its own needs but also powering global supply chains. As these efforts continue, the country’s vision of becoming a global electronics hub is fast turning into a tangible reality.

References:

PIB Backgrounders:

Ministry of Commerce and Industry:

Click here for pdf file.

****

SK/SA

(रिलीज़ आईडी: 2183028)

आगंतुक पटल : 5829