Ministry of Science & Technology

Photoactive natural protein could reshape the future of electronic materials

Posted On:

09 JAN 2026 7:48PM by PIB Delhi

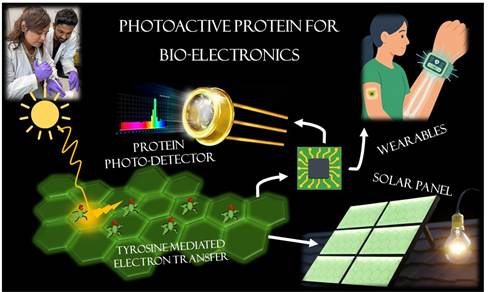

A newly discovered semiconductor property of a known self-assembling bacterial shell protein could pave the way for safe, environmentally friendly electronics—from mobile phones and smart watches to medical instruments and environmental sensors.

Traditional semiconductor materials, such as silicon, are valuable technological tools but come with limitations. They are rigid, require high-energy processing, and contribute to the growing problem of electronic waste. Thus, there is increasing demand for sustainable, soft, and biocompatible electronics (wearables, implantable, green sensors).

A team of scientists from Institute of Nano Science and Technology (INST), Mohali, an autonomous institute of the Department of Science and Technology (DST) experimenting with self-assembling bacterial shell proteins explored whether the proteins that naturally form stable, large flat 2D sheets with built-in electron density patterns and aromatic residues, could be intrinsically photoactive.

A research team led by Dr. Sharmistha Sinha, together with student researchers Ms. Silky Bedi and Mr. S. M. Rose, found that when the proteins form flat, sheet-like films they absorb UV light and generate an electrical current without any added dyes, metals, or external power and act as light-driven, scaffold-free semiconductors, much like the materials used in electronic circuits and sensors.

The researchers discovered that these proteins naturally arrange themselves into thin, sheet-like structures. When UV light shines on them, tiny electrical charges begin to move across the protein surface. This happens because the proteins contain tyrosine, a natural amino acid that can release electrons when excited by light. As these electrons and protons move, the protein sheet produces an electrical signal—similar to how a miniature solar cell would operate. This light-driven effect relies on the protein’s internal order and does not require any synthetic additives or high-temperature manufacturing.

Fig: Self-assembled shell protein sheets with semiconducting and photoresponsive properties for next generation bio-electronic material

The discovery opens up exciting possibilities for real-world applications. Because the material is flexible and body-friendly, it could be used to create wearable health monitors, skin-safe UV-detection patches, and implantable medical sensors that work safely inside the human body. It could also be used in temporary or disposable environmental sensors, such as pollution detectors or sunlight trackers, that naturally break down after use without harming the environment. Families, patients, and consumers may one day benefit from soft, comfortable, and environmentally responsible devices that integrate smoothly into daily life.

To reach this understanding, the INST team examined how the proteins assemble, how they behave under light, and how electricity moves across them. Using advanced microscopes and precisely controlled electrical tests, the researchers confirmed that this semiconductor-like behaviour depends on the protein’s neatly arranged structure and on the special orientation of tyrosine residues at the central region of the protein. By comparing the results with unfolded or disordered proteins having tyrosine, the team demonstrated that the effect is unique to the naturally ordered protein sheets.

The study, published in the journal Chemical Science of the Royal Society of Chemistry represents a promising step toward bio-inspired electronics, where materials are designed by learning directly from the ingenious mechanisms found in nature. Such materials could lead to a new generation of electronic technologies that are not only functional and efficient, but also sustainable, safe, and aligned with the needs of both people and the planet.

This could provide a genetically tunable, low-energy route to make light-sensitive materials that are useful for low-cost detectors, biocompatible sensors and safe less invasive implantable devices.

Publication link: DOI: 10.1039/D5SC05716G

*****

NKR/AK

(Release ID: 2213034)

Visitor Counter : 1468